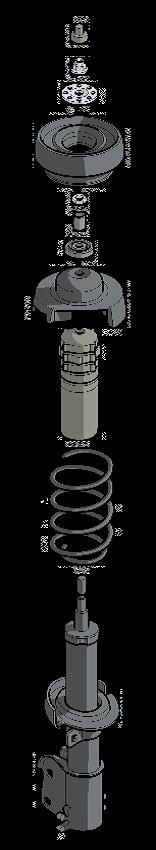

The Macpherson strut is made up of a variety of components to form a compact suspension unit. This is a very popular choice for vehicle manufacturers due to its simplicity and low manufacturing costs.

The main part of this suspension unit is a long telescopic tube that incorporates a shock absorber. This is usually fitted with a piston guard to keep out road sand and to protect the seals. A coil spring sits between two retaining cups. This is held in place under compression by a retaining nut that is attached to the top of the shock absorber piston.

The unit is rigidly connected to the stub axle or hub assembly. It is pivoted at the top, usually by an upper bearing, to accommodate the steering movement. The bearing is part of the upper strut mounting assembly which acts as an insulator and mounting point between the suspension unit and the vehicle body. (Fig. 1)

Features of a strut mount

The upper suspension strut mount is a bonded rubber bushing that is mounted on top of the shock absorber and secured to the vehicle frame. This is an integral part of the suspension strut assembly. Strut mounts may also incorporate a bearing or carrier plate that allows the strut to pivot with the steered wheels.

The strut mount acts as a coupling to the spring and shock absorber, connecting it to the body. The damping force is absorbed separately within the mount, which in turn isolates the vehicle body from the suspension and road noise.

In the lateral direction, the mounting is designed to be more rigid. This positively influences the driving dynamics and steering response. This significantly reduces noise, vibrations and harshness of the transmission and suspension, ensuring maximum comfort for the driver and passenger.

To this end, the upper strut mount must provide low-friction, distortion-free movement of the shock absorber spring during steering and deflection. This allows the road spring to operate without a self-aligning torque. The strut mount must also position the shock absorber spring and form a support surface for full shock absorber deflection.

All this must be achieved in a compact design, optimized for limited mounting space and supplied as a sealed unit. It must also be maintenance-free.

Replacing the upper part of the strut

During the life of this suspension unit, the shock absorber and spring must expand and contract millions of times, taking the stress of road surfaces. This includes damaged road surfaces that place additional stress on the unit. (Fig. 2)

The upper strut mount bearing often comes apart or seizes up, causing a creaking or grinding noise from the suspension. This can cause the bearing to break the rubber in the mount (Fig. 3). The rubber itself can deteriorate with age, reducing ride comfort due to noise development.

This results in tight steering or excessive steering play, unstable handling, and reduced driving and braking safety. This allows water to infiltrate and provides unnaturally high wear. The result: there is too much play in the joint which leads to the aforementioned noises.

The strength of a strut mount comes from the properties of the elastomer material used and the metal reinforcement within it. This provides the necessary flexibility and rigidity. Figure 4 shows a sectional view of febi part 22639 with the included bearing. febi strut top mounts are made from OE quality rubber and follow the exact specifications of the vehicle manufacturer for optimum performance.